Babcock and Wilcox Boiler – Construction, Working, Application, Advantages and Disadvantages January 31, 2017 December 25, 2018 Pankaj Mishra 0 Comments boiler, Boilers In this article we will learn about Babcock and Wilcox Boiler- Main parts, working, advantages and disadvantages with application. The Babcock & Wilcox Company Company Overview An Image/Link below is provided (as is) to download presentation. Download Policy: Content on the Website is provided to you AS IS for your information and personal use and may not be sold / licensed / shared on other websites without getting consent from its author.

Coffee Roomover the body of the boiler itself for the safety of the boiler and for

complete control of the process of steam generation.

Various boiler mountings are as under:

1) Pressure gauge

2) Water Level Indicator

3) Fusible plug

4)Safety Valve

i) Lever Safety Valve

ii) Spring Loaded safety Valve

5) Steam stop valve

6) Feed check valve

7) Blow off cock

Function:

1.To record the steam pressure at which the steam is generated in the boiler.

2. A bourdon pressure gauge in its simplest form consists of elliptical elastic tube bent into an arc of a circle

3. This bent up tube is called as BOURDON’S tube.

4. One end of tube gauge is fixed and connected to the steam space in the boiler.

The other end is connected to a sector through a link.

• The function of water level indicator is to indicate the level of water in the boiler constantly.

• It is also called water gauge.

• Normally two water level indicators are fitted at the front end of every boiler.

• Function: To extinguish fire in the event of water level in the boiler shell falling below certain specified limit.

• It protects fire tubes from burning when the level of the water in the water shell falls abnormally low and the fire tube or

crown plate which is normally submerged in the water, gets exposed to steam space which may not be able to keep it

cool.

• It is installed below boiler's water level.

• When the water level in the shell falls below the top of the plug, the steam cannot keep it cool and the fusible metal

melts due to over heating. Thus the copper plug drops down and is held within the gunmetal body by the ribs. Thus the steam space gets

communicated to the firebox and extinguishes the fire. Thus damage to fire box which could burn up is avoided.

• By removing the gun metal plug and copper plug the fusible plug can be put in position again by interposing the fusible

metal usually lead or a metal alloy.

Function : The function of safety valve is to release the excess steam when the pressure of steam inside the boiler exceeds

the rated pressure.

There are 4 types of safety valves:

i) Lever Safety Valve

The disadvantage of this valve is that it admits of being tempered with, and the effect of

a small addition to the weight is magnified considerably in its action on the value.

ii) Spring Loaded safety Valve

• For locomotives and marine engines both the lever and dead weight types are unsuitable for obvious reasons,

and the valve must be spring loaded, as such valve is unaffected by vibration or deviation from the vertical.

• Disadvantage :

One disadvantage of this valve is that the load on the valve increases as the valve lifts, so that pressure required

just to lift the valve is less than that required to open it fully.

iii)Dead Weight Safety Valve

• It is mainly used for low pressures, low capacity, stationary boilers of the Cornish and Lancashire types.

• Merits:

1)Simplicity of design

2)Gives quite a satisfactory performance during operation.

3)It cannot be easily tempered from the pressure adjustment view.

• Demerits:

1)Unsuitable for use on any boiler where extensive vibration and movement are experienced( e.g. locomotive and marine work).

2)It is not suitable for high pressure boilers because a large amount of weight is required to balance the steam pressure.

iv) High steam and low water safety valve

• It serves the following purposes.

(i) The steam automatically escapes out when the level of water falls below a certain level.

(ii) It automatically discharges the excess steam when the pressure of the steam rises above a certain pressure.

Use : It is generally used on Lancashire or Cornish boiler.

It cannot used in mobile boilers.

Badcock And Wilcox Boiler Ppt File Online

• A valve is a device that regulates the flow of a fluid (gases, fluidized solids, slurries, or liquids) by opening,

closing, or partially obstructing various passageways.

• Function: to shut off or regulate the flow of steam from the boiler to the steam pipe or steam from the steam

pipe to the engine.

• When the hand wheel is turned, the spindle which is screwed through the nut is raised or lowered depending

upon the sense of rotation of wheel. The passage for flow of steam is set on opening of the valve.

Function: The function of a feed check valve is to control the supply of water

to the boiler and to prevent the escaping of water from the boiler when the pump pressure is less or pump is stopped.

i) To allow the feed water to pass into the boiler.

ii) To prevent the back flow of water from the boiler in the event of the failure of the feed pump.

The feed check valve is fitted in the water space of the boiler slightly below the normal level of the water.

• Function: To drain out the water from the boiler for internal cleaning, inspection, repair or other purposes.

• It may discharge a portion of water when the boiler is in operation to blow out mud, scale or sediments, periodically.

• It is fitted on the boiler shell directly or to a short branch pipe at the lowest part of the water space.

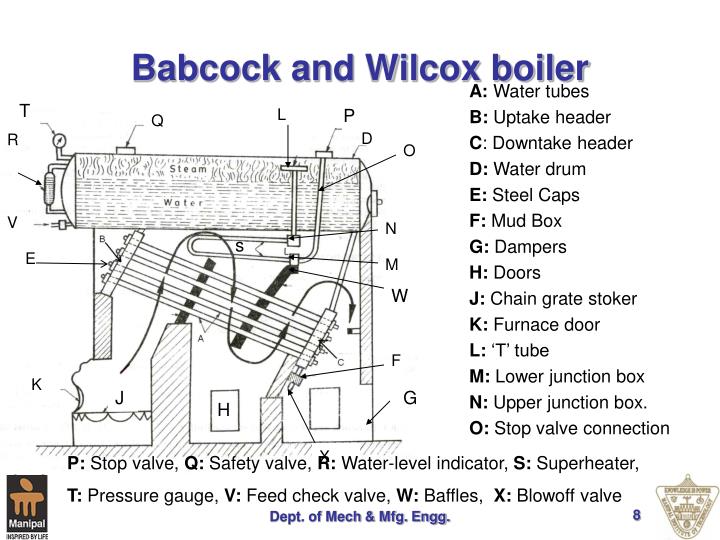

Manhole provides opening for cleaning, inspection and maintenance

purpose. Mud box is a collection chamber (as shown in Babcock and Wilcox boiler) for collecting the Mud

.

Superb job..

Bows to you. You rock buddy.

CEans please add the other mountings to it so that we can forge a nice tutorial out of it.

1. Water level indicator. (Water gauge)

2. Main steam stop valve.

3. Pressure gauge.

4. Feed check valve.

5. Fusible plug.

6. Blow down valve. (Blow off cock)

7. Air vent.

8. Safety valve.

1. Water level indicator.

2. Main steam stop valve.

3. Pressure gauge.

4. Feed check valve.

5. Fusible plug.

6. Blow down valve.

7. Air vent. (air cock)

8. Safely valve.

plz give me today itself!!!!!!

1) Economizer

2 Superheater

3 pre-heater and etc

Babcock And Wilcox Boiler Ppt Files

1.Horizontal, Vertical or Inclined Boiler.

If the axis of the boiler is horizontal,the boiler is called horizontal, if the axis is vertical, it is called verticalboiler and if the axis is inclined it is called as inclined boiler.The parts of horizontal boiler is can be inspected and repaired easily but it occupies more space.The vertical boiler occupies less floor area.

2.Fire Tube and Water Tube

In the fire boilers, the hot gases are inside the tubes and the water surrounds the tubes.

Examples: Cochran, Lancashire and Locomotive boilers.

In the water tube boilers, the water is inside the tubes and hot gases surround them.

Examples: Babcock and Wilcox,

Stirling, Yarrow boiler etc.

3.Externally Fired and Internally Fired

The boiler is known as externally fired if the fire is outside the shell.

Examples: Babcock and Wilcox boiler,Stirling boiler etc.

In case of internally fired boilers, the furnace is located inside the shell.

Examples: Cochran, Lancashire boiler etc.

4.Forced circulation and Natural Circulation

In forced circulation type of boilers, the circulation of water is done by a

forced pump.

Examples: Velox,Lamomt,Benson Boiler etc.

In natural circulation type of boilers, circulation of water in the boiler takes

place due to natural convention currents produced by the application of

heat.

Examples: Lancashire, Babcock and Wilcox boiler etc.

5.Higher Pressure and Low Pressure Boilers

The boiler which produce steam at pressures of 80 bar and above are

called high pressure boilers.

Examples: Babcock and Wilcox, Velox,Lamomt,Benson Boiler etc.

The boilers which produce steam at pressure below 80 bar are called low

pressure boilers.

Examples: Cochran, Cornish, Lancashire and Locomotive boiler etc.

6. Stationary and Portable

• Primarily, the boilers are classified as either stationary or mobile.

• Stationary boilers are used for power plant steam, for central station utility

power plants, for plant process steam etc.

• Mobile boilers or portable boilers include locomotive type, and other small

units for temporary use at sites.

7. Single Tube and Multi Tube Boiler

The fire tube boilers are classified as single tube and multi-tube boilers,

depending upon whether the fire tube is one or more than one.

Examples: Cornish ,simple vertical boiler are the single tube boiler and rest

of the boilers are multi-tube boiler.

Why steam generated by Babcock and Wilcox Boiler has more pressure compared to Cochran Boiler? Assume both of same size.

Babcock And Wilcox Boiler Ppt File Size

The whole point is that the Babcock-Wilcox is a water tube boiler designed for large volumes of steam, while the Cochran one is a firetube one for small plants designed with a small foot print.

Babcock And Wilcox Boiler Ppt File

They are meant for different applications.